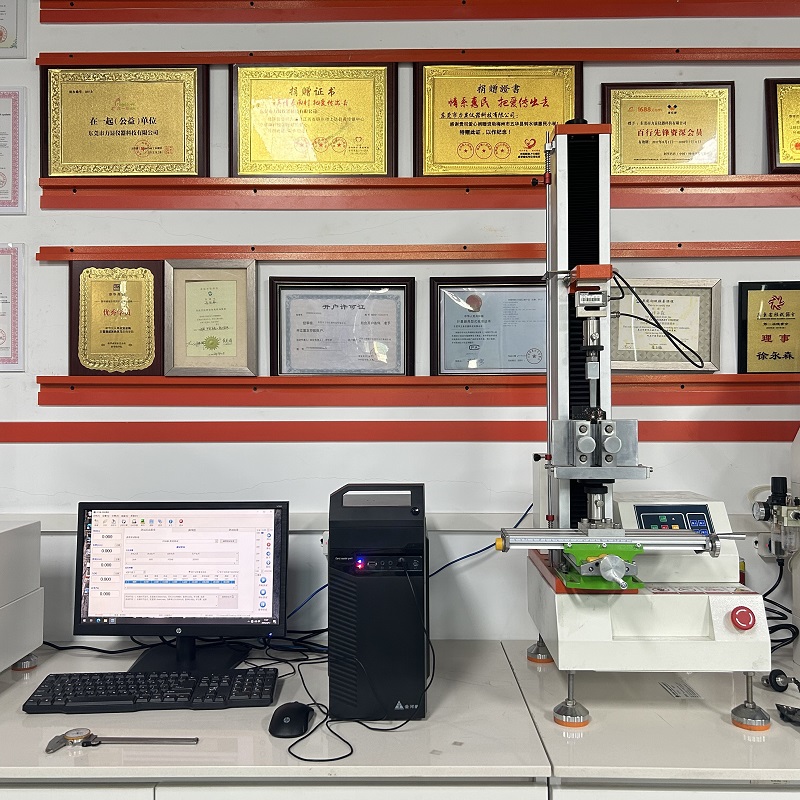

The PAN (polyacrylonitrile)-based carbon fiber tensile testing machine is primarily suitable for performing physical property tests such as tension, bending, compression, shear, peeling, tearing, puncture, and cycling on rubber, plastics, composite materials, metals, non-metallic products. It is widely used for material analysis and inspection in industries such as plastics, rubber, leather, textiles, wire and cable, metals, building materials, aerospace, and petrochemicals. It can perform tests and process data according to various standards such as GB, ISO, JIS, ASTM, and DIN. It is an ideal testing equipment for the rubber and plastics industry, research institutes, universities, commodity inspection and arbitration, and technical supervision departments.

Model | HZ-1007E |

Maximum load | 10N,20N,50N,100N,200N, 500N, 1KN option |

Accurate grade | 1grade/0.5 grade |

Effective measuring range | 0.2%~100%/0.4%~100% |

Measuring accuracy | The value ±1%/ the value ±0.5% |

Tester resolution | Max load 1/200000, constant the resolution |

Load sensor | Chinese brand, (Transell brand)USA,Tecics(Germany),Optional |

Effective tensile stroke | 300mm |

Range of testing speed | 0.01~500mm/min (Special can be 0.01-1000mm/min) |

Accuracy of displacement | Tolerance: ±0.5%/ tolerance: ±0.2% |

safety | Electronic-limit protection |

Platform moving device | Fast /slow two speeds to control,can jog |

Overload protection | Overload 10%, automatic protection |

Grips | Tensile grip, Compression, Peel grip, Bending grip, Optional |

Machine size | 40x45x120cm (length*width*height) |

Motor | Delta AC servo motor and drive |

Power supply | 220V, 50HZ |

power | 400W |

weight | About 50 KG |

Unit | KG,N,LB, TON can be exchanged. |