- Product Details

As the most common and important test type in material mechanics testing, the key to achieving effective and accurate tensile test results lies in whether the appropriate tensile fixture can be selected. Tensile fixtures are divided into manual flat-push fixtures, manual wedge fixtures, pneumatic flat-push fixtures, pneumatic wedge fixtures and hydraulic fixtures.

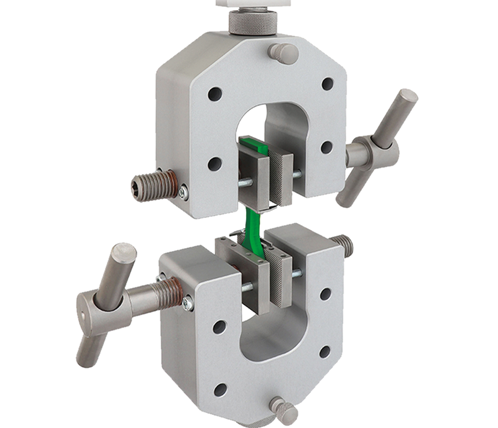

Flat-push tensile fixtures are a very common and practical clamping tooling. Flat-push tensile fixtures are widely used and can simply and effectively clamp specimens. Almost all specimens can be well fixed by this flat-push clamping method. Through double-sided flat-push or single-sided flat-push design, the fixture opening can be adjusted to adapt to different specimen thicknesses to ensure that the specimen force and the fixture are on the same axis. The fixture can be equipped with replaceable clamping faces of various sizes, and various surface forms such as metal smooth surface, rubber coating and serration can be selected to adapt to different materials. Flat-push tensile fixtures are mainly distinguished according to the different test force sizes. When selecting, appropriate fixtures and clamping faces can be selected according to the different force, sample and environmental conditions.

Applications:

Load types: tensile, static and tension-tension cyclic tests, not suitable for high-cycle dynamic fatigue tests

Specimen materials: plastics, metals, textiles, paper, sheets, foils, wires, etc.

Specimen shapes: components, bars (wires) and flat specimens, with or without shoulders