Textile Tensile Testing Machines: Ensuring Strength and Durability in Fabric Performance

In the textile industry, the quality and reliability of fabrics are paramount. Whether for apparel, technical textiles, or industrial applications, understanding a material’s tensile properties is critical to ensuring it meets performance standards.

A textile tensile testing machine is an indispensable tool for manufacturers, quality control teams, and research laboratories to evaluate the strength, elongation, and durability of textiles under controlled conditions.

Tensile testing measures how a fabric responds to stretching forces until it breaks. This process provides essential data, including:

Maximum Load Capacity: The force a fabric can withstand before failure.

Elongation at Break: The extent to which a material stretches before breaking.

Modulus of Elasticity: Resistance to deformation under stress.

Work to Rupture: Energy absorbed during the test.

These metrics are vital for applications ranging from everyday clothing to high-performance textiles used in aerospace, medical devices, or protective gear.

---

Key Features of Modern Textile Tensile Testing Machines

Advanced tensile testers are designed to deliver precision, versatility, and compliance with global standards such as ASTM D5034, ISO 13934-1, and EN ISO 13935-2. Key features include:

1. Adaptable Gripping Systems: Pneumatic, manual, or specialized clamps to securely hold diverse fabrics (woven, nonwoven, knits) without slippage or damage.

2. High-Resolution Load Cells: Accurate force measurement across a wide range (from 0.1 N to 50 kN) for testing delicate fibers to heavy-duty industrial textiles.

3. Customizable Test Parameters: Adjustable speed, pre-tension settings, and multi-test modes (grab, strip, or loop tests).

4. Intuitive Software: Real-time data visualization, automated calculations, and exportable reports for seamless integration into quality workflows.

5. Durability & Safety: Robust construction with overload protection and emergency stop functions.

---

Applications Across the Textile Industry

1. Apparel & Fashion: Verify stretch recovery in activewear or denim durability.

2. Medical Textiles: Test the strength of surgical gowns, masks, or implantable meshes.

3. Automotive & Aerospace: Evaluate seatbelt webbing, airbag fabrics, or composite reinforcements.

4. Geotextiles: Assess resistance to environmental stress in erosion control materials.

5. Research & Development: Innovate new fabric blends or sustainable materials with precise tensile data.

---

Choosing the Right Tensile Tester

When selecting a textile tensile testing machine, consider:

- Material Compatibility: Ensure the machine accommodates your fabric’s thickness and structure.

- Regulatory Compliance: Align with industry-specific standards (e.g., AATCC, ISO).

- Automation Needs: Opt for systems with barcode scanning or batch testing for high-throughput labs.

- Technical Support: Partner with suppliers offering calibration, training, and maintenance services.

---

Conclusion

A textile tensile testing machine is more than just a quality control tool—it’s an investment in product integrity and customer trust. By quantifying a fabric’s mechanical behavior, manufacturers can optimize production processes,

reduce waste, and deliver textiles that exceed performance expectations.

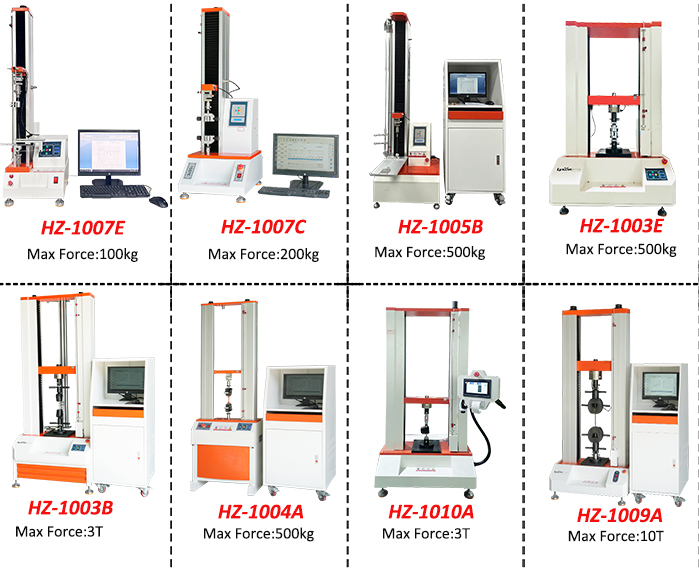

At Lixian Instrument , we provide state-of-the-art tensile testing solutions tailored to the textile industry’s evolving demands. Explore our range of machines and software designed to empower your quality assurance journey.

Learn more about our tensile testing technology and request a demo today!